1 月 . 15, 2025 00:39 Back to list

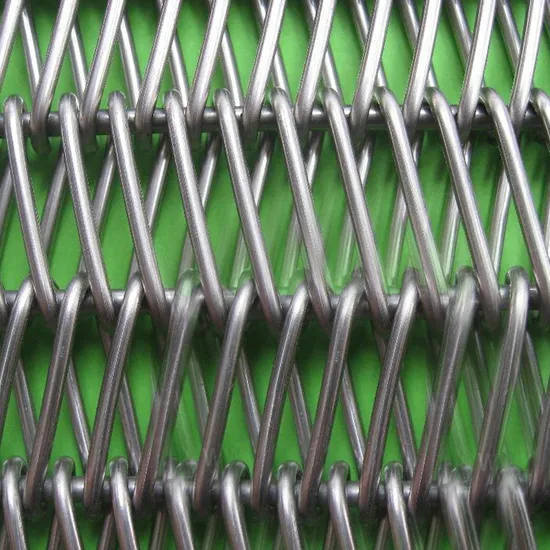

galvanised steel grid

Beyond their physical properties, galvanised steel grids represent a commitment to sustainable practices. Their extended lifespan means they require fewer resources for production over time, reducing their environmental footprint. This sustainability aspect appeals to savvy consumers seeking environmentally friendly solutions in industrial or domestic projects. Moreover, recycling galvanized steel is straightforward and energy-efficient, further minimizing ecological impact. From an authoritative perspective, galvanised steel grids are essential across industries due to stringent manufacturing standards that assure quality and consistency. Certified by numerous international bodies for safety and performance, these grids align with global best practices, further solidifying their reputation. Such certifications and endorsements provide users with peace of mind, knowing the products they choose have undergone rigorous testing and approval processes. For those seeking to integrate galvanized steel grids into their operations, consulting with industry specialists or suppliers can provide tailored advice. Professional recommendations based on specific project needs can enhance outcomes, whether the aim is to bolster infrastructure, improve agricultural efficiency, or reduce long-term maintenance costs. In summary, the reliability, versatility, and sustainability of galvanised steel grids make them a trustworthy choice for those who prioritize quality and competence. Their broad acceptance and application across various sectors underscore a legacy built on performance, making them an ideal investment for future-ready projects. Through their unparalleled resilience and authoritative backing, galvanised steel grids remain a staple in modern industries, embodying the principles of reliability and environmental responsibility.

Latest News

-

High-Quality Plastic Poultry Mesh – Durable, UV-Resistant Chicken Netting for Gardens & Farms

NewsJun.10,2025

-

Galvanised Driveway Grates for Heavy Duty Drainage Durable Storm Drain Grates

NewsJun.10,2025

-

High-Quality Fiberglass Mesh China Durable & Affordable Solutions

NewsMay.30,2025

-

100 Ft Chain Link Fence Prices & Installation Durable Solutions

NewsMay.30,2025

-

Chain Link Fence Cost Per Foot Affordable & Durable Solutions

NewsMay.30,2025

-

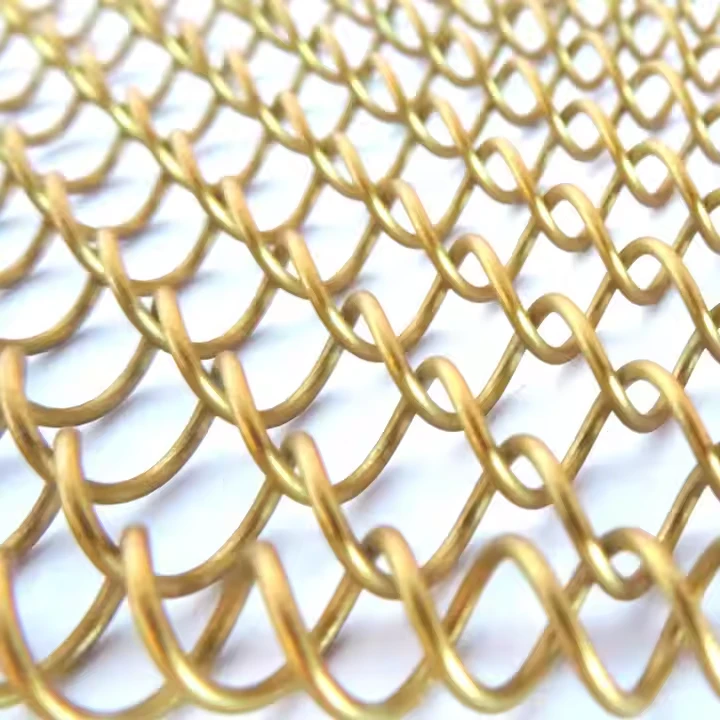

Wire Mesh Decorative Cabinet Door Inserts Durable & Stylish Designs

NewsMay.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA