12 月 . 06, 2024 04:45 Back to list

cloth woven wire scraping mesh

The Versatility of Woven Wire Scraping Mesh An Overview

In the realm of industrial and commercial applications, the importance of efficient filtering and separation mechanisms cannot be overstated. One such solution that has garnered significant attention is the woven wire scraping mesh. This product has emerged as a staple in various industries, including agriculture, food processing, construction, and mining. Defined by its unique design and functional characteristics, woven wire scraping mesh offers a reliable means of separating different materials, preventing contamination, and ensuring quality in production processes.

Composition and Design

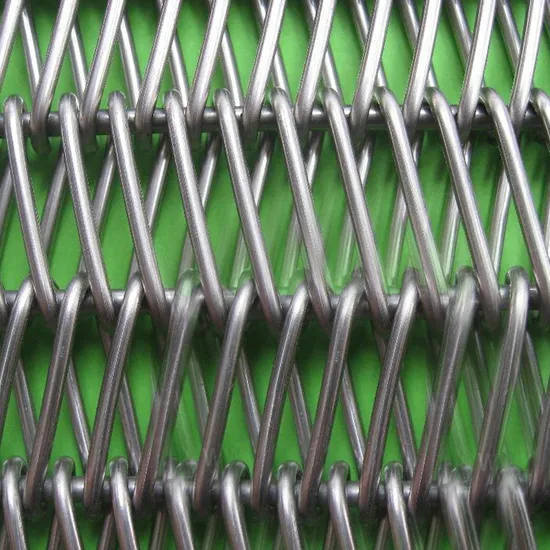

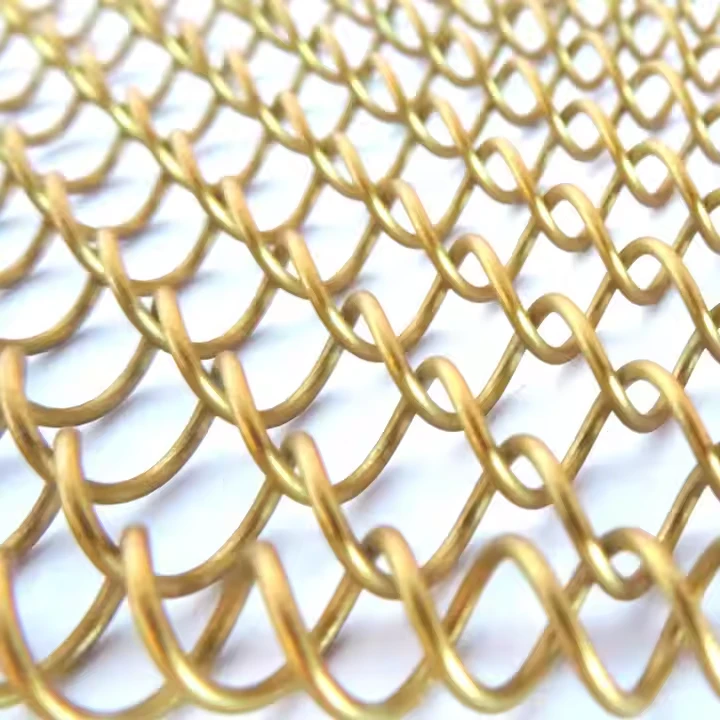

Woven wire scraping mesh is typically fabricated from high-quality stainless steel, carbon steel, or other alloy materials, ensuring durability and longevity. Its design consists of interwoven wire strands that create a flexible yet robust mesh. This structure allows for high tensile strength while maintaining a lightweight profile, making it ideal for applications where traditional filtering might fail. The mesh can be produced in a variety of configurations—such as plain weave, twill weave, or Dutch weave—tailoring its characteristics to meet specific needs.

Key Applications

1. Agriculture In agricultural settings, woven wire scraping mesh plays a crucial role in the processing of grains, seeds, and other products. Its ability to filter out impurities and ensure that only the desired particles pass through is essential for maintaining the quality and safety of food products. Farmers and food manufacturers rely on this mesh to create clean, safe produce that adheres to health standards.

2. Food Processing The food industry, governed by strict regulations, has found woven wire scraping mesh invaluable. It is used in various stages of food processing, from screening raw ingredients to filtering liquids. The mesh is resistant to corrosion and can be easily sanitized, making it suitable for environments that require high levels of hygiene.

3. Construction and Mining In construction and mining, the mesh is used to separate materials such as gravel, sand, and other aggregates. Its robustness allows it to withstand harsh working conditions while efficiently sorting materials by size. This not only improves the efficiency of material handling but also enhances the safety of operations by preventing large particles from causing obstructions.

cloth woven wire scraping mesh

4. Environmental Applications Woven wire scraping mesh also finds application in environmental management, particularly in water treatment processes. It can be employed to filter out debris and particulate matter from water supplies, ensuring the cleanliness of water resources. Its use in waste management, such as composting and recycling, aids in separating organic waste from other materials, fostering sustainable practices.

Advantages of Woven Wire Scraping Mesh

One of the primary benefits of woven wire scraping mesh is its adaptability. It can be customized in terms of mesh size, wire diameter, and even coating to cater to different operational requirements. Furthermore, its resistance to wear and tear extends the life of the product, reducing costs associated with frequent replacements.

Another significant advantage is its easy maintenance. Cleaning and retightening the mesh is a straightforward process, allowing for minimal downtime in production line settings. This factor is particularly important in high-volume industries where efficiency and productivity are critical.

Conclusion

As industries evolve and the demand for efficiency and quality control increases, woven wire scraping mesh stands out as a pivotal tool in ensuring optimal separation and filtration processes. Its versatility across various sectors demonstrates not only its practicality but also its importance in meeting regulatory standards for safety and quality.

In summary, woven wire scraping mesh is an essential component for numerous applications, from agriculture to environmental protection. By understanding the unique characteristics and benefits of this product, industries can leverage its capabilities to streamline operations, enhance product quality, and ultimately meet the challenges posed by modern manufacturing and processing demands. As technology advances, we can expect even more innovative applications for woven wire scraping mesh, solidifying its role as an indispensable asset in industrial practices.

Latest News

-

High-Quality Plastic Poultry Mesh – Durable, UV-Resistant Chicken Netting for Gardens & Farms

NewsJun.10,2025

-

Galvanised Driveway Grates for Heavy Duty Drainage Durable Storm Drain Grates

NewsJun.10,2025

-

High-Quality Fiberglass Mesh China Durable & Affordable Solutions

NewsMay.30,2025

-

100 Ft Chain Link Fence Prices & Installation Durable Solutions

NewsMay.30,2025

-

Chain Link Fence Cost Per Foot Affordable & Durable Solutions

NewsMay.30,2025

-

Wire Mesh Decorative Cabinet Door Inserts Durable & Stylish Designs

NewsMay.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA