1 月 . 17, 2025 04:18 Back to list

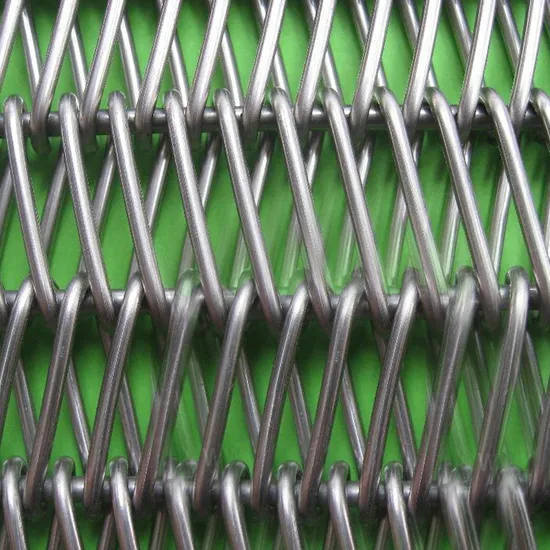

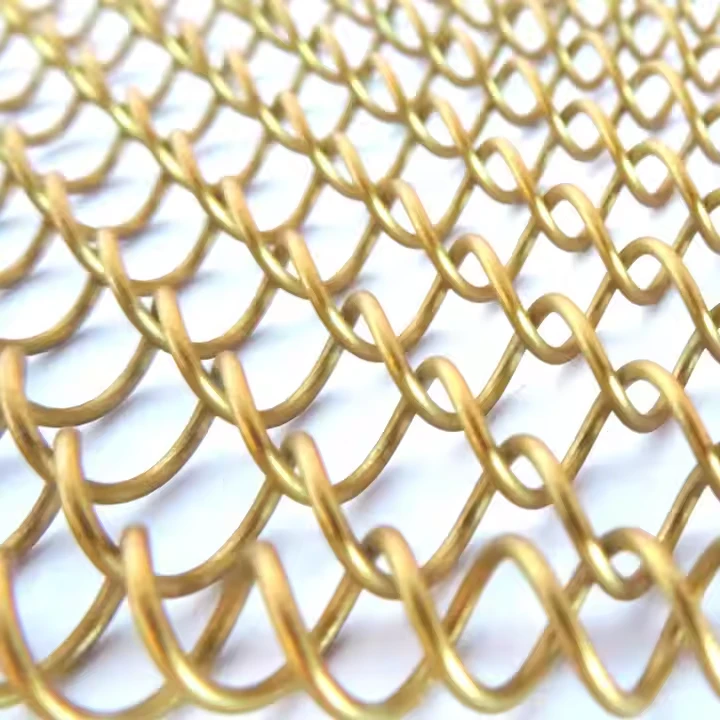

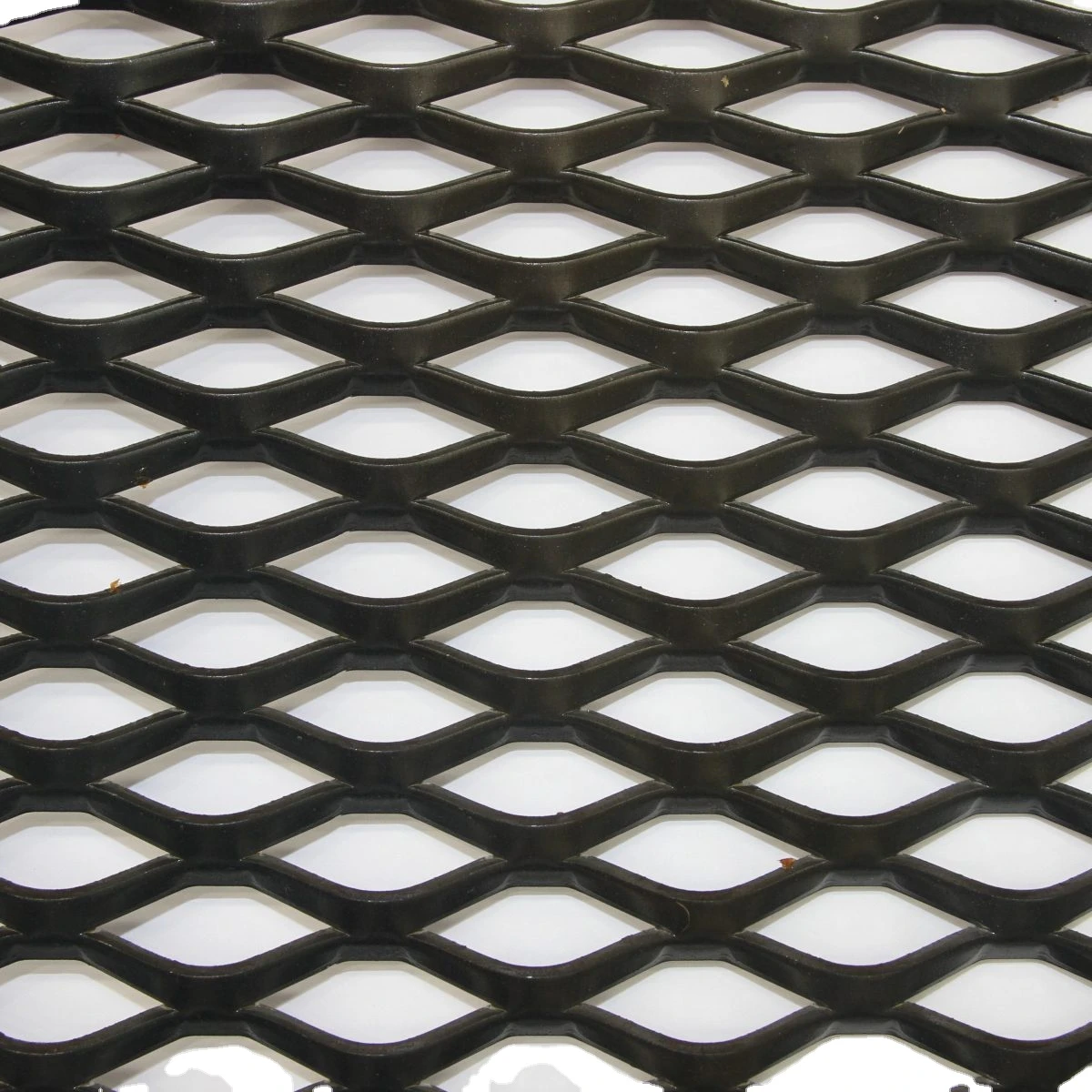

Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

Trustworthiness is established when suppliers and professionals in the grating industry demonstrate transparency and reliability. This relates to thorough testing and validation of the gratings’ performance under various environmental conditions. Trust is further built through testimonials and case studies highlighting successful projects, showcasing not just a product, but a history of effective application of black grating solutions under diverse conditions and challenges. In terms of product innovation and sustainability, black grating also represents strides forward in environmentally-conscious design. Manufacturers are increasingly adopting sustainable practices, using recycled materials without compromising on strength and durability. These innovations meet the rising demand for greener solutions in construction and development, adding another layer of trust and credibility for providers adhering to such principles. Moreover, the aesthetic value of black grating, while often secondary to functionality, plays a crucial role in commercial and public sectors. Architects and designers choose black grating not just for its robustness, but its ability to seamlessly integrate into modern architectural aesthetics. The sleek, understated look serves to complement the overall visual theme without overshadowing other elements of the design. In conclusion, black grating is a versatile and indispensable component across a variety of applications, from industrial settings demanding high-load capacities and anti-slip properties, to cutting-edge architectural projects prioritizing aesthetic integration and sustainability. Mastery over the aspects of experience, expertise, authority, and trustworthiness can significantly enhance the decision-making process, ensuring that the chosen grating meets both project specifications and environmental considerations. Selecting the right black grating involves navigating a landscape of technical specifications, industry standards, and design requirements—a task requiring the balance of practical experience with specialized knowledge.

Latest News

-

High-Quality Plastic Poultry Mesh – Durable, UV-Resistant Chicken Netting for Gardens & Farms

NewsJun.10,2025

-

Galvanised Driveway Grates for Heavy Duty Drainage Durable Storm Drain Grates

NewsJun.10,2025

-

High-Quality Fiberglass Mesh China Durable & Affordable Solutions

NewsMay.30,2025

-

100 Ft Chain Link Fence Prices & Installation Durable Solutions

NewsMay.30,2025

-

Chain Link Fence Cost Per Foot Affordable & Durable Solutions

NewsMay.30,2025

-

Wire Mesh Decorative Cabinet Door Inserts Durable & Stylish Designs

NewsMay.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA